KGSPL is a leading provider of industrial Piping design engineering services and fabrication services, catering to a diverse range of segments and industries. We specialize in collaborating closely with industrial facilities to deliver comprehensive solutions, encompassing the design, fabrication, testing, and installation of piping systems.

At KGSPL, we have state-of-the-art facilities located in Tamil Nadu, where we fabricate the piping systems with the highest level of precision and quality. Alternatively, we also offer on-site fabrication services, ensuring flexibility and convenience for our clients. Our team of experienced professionals ensures that all fabrication processes adhere to strict quality control measures, complying with customer specifications and industry standards.

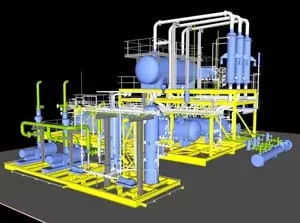

Or piping design and engineering involve the creation of detailed plans and specifications for the design, layout, and installation of piping systems. This is crucial for ensuring the safe and efficient transportation of fluids, such as water, gasses, chemicals, and petroleum products, within a facility or between different facilities.

Our fabrication procedures undergo rigorous validations, specifically tailored to meet the unique requirements of each application and industry. This meticulous approach guarantees the structural integrity of the piping systems, providing our clients with reliable and durable products. We understand the criticality of ensuring compliance, safety, and operational efficiency, and our fabrication processes reflect these considerations.

In addition to our piping fabrication services, KGSPL offers a comprehensive range of products, including atmospheric tanks, pipe racks, modules, skids, instrument racks, and complete packages. This integrated approach allows us to provide cost-efficient and safe systems to our clients, minimizing time and integration costs at their end. By offering a diverse portfolio of products, we ensure seamless compatibility and functionality between various components, enhancing the overall performance and reliability of the systems.

Moreover, KGSPL places great emphasis on customer satisfaction and collaboration. We work closely with our clients throughout the entire project lifecycle, from conceptualization to installation and beyond. Our team of experts leverages their industry knowledge and technical expertise to provide tailored solutions that meet the specific needs of each client and project.

We are committed to delivering the highest quality industrial piping fabrication services. With our advanced facilities, rigorous quality control processes, and comprehensive range of products, we offer reliable, efficient, and safe piping systems that meet the diverse requirements of our clients across various industries.